The demand for wearable e-skin devices is on the rise, particularly in industries such as biomedical, surgical robotics, and brain-computer interface. These devices are crucial for real-time monitoring of health signals, offering invaluable insights for both patients and healthcare professionals. However, the existing e-skin devices face significant challenges in terms of structure and fabrication, limiting their effectiveness and usability.

One of the main challenges with current e-skin devices is their complex structure and fabrication process. Achieving high precision and accuracy in the fabrication of these devices is extremely difficult, often leading to suboptimal performance. Additionaly, existing e-skin sensors lack of sensitivity and precision required for accurate health monitoring, limiting their potential applications in the healthcare industry.

Innovation in Sensor Healthcare Technology

Precision Fabrication with BMF MicroArch® 3D Printing Technology

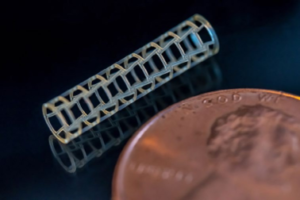

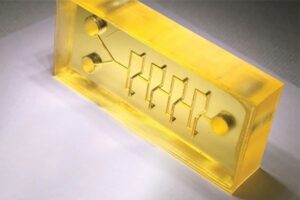

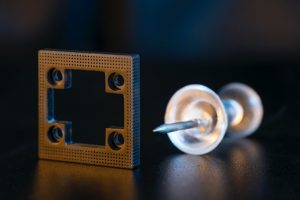

MicroArch® S130, from BMF 2μm series of micro additive manufacturing solutions, is an ideal option for educational and research institutions with requirements for ultra-high resolution, accuracy, and precision. BMF micro AM technology can print high-precision and complex structural models, such as electronic sensors, e-skin sensors, and microfluidics, for wearable devices.

Constant and advanced research will be helpful in innovative products that are extremely inclusive, beneficial and efficient. The fitness and improvement in people’s lifestyles will also drive the demand for healthcare market during the forecast period.

Looking for microArch 3D printing technology for your healthcare application?

Our technical team will help your needs