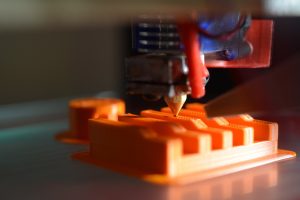

3D Printing with Soft TPE Polymer

Open material 3D printers can now utilize soft polymers such as TPE, a polymeric material with elastomeric behavior and processability of thermoplastics. Find out more about it’s benefits!

Viscometers are used in the measurement of the viscosity and flow behavior of fluids. Viscometers can measure both Newtonian and non-Newtonian fluids. A Newtonian fluid’s viscosity remains constant, no matter the amount of shear is applied for a constant temperature. For non-Newtonian fluid, the viscosity will change under shear force.

Viscometers are widely used in various applications, including food products, chemicals, paints and coatings, inks, cosmetics, pharmaceuticals, adhesives, oils, latex and others.

Going through those questions above and still need an expert to choose the best viscometer for you? Maha has got you covered. Send in your enquiry at Sales@maha.asia or contact us at 6863 1808.

Open material 3D printers can now utilize soft polymers such as TPE, a polymeric material with elastomeric behavior and processability of thermoplastics. Find out more about it’s benefits!

Microfluidics is the study of fluid behavior in microscale channels, this has become increasingly important for medical and laboratory diagnostics. 3D printing can produce intricate objects like microfluidic devices, however few can create microscale components with the right features, tolerances, resolution and desired desired speed.

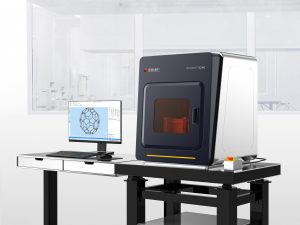

What is 3D printing work? How is it different from other manufacturing techniques? The answers to these questions might surprise you. There at several different types, there isn’t just one form of 3D printing. They all build parts by depositing material one layer at a time, but there are important differences in terms of 3D printing technologies, the materials supported, the part sizes that can be produced, and the accuracy, resolution and precision that the 3D printers can achieve.

Copyright © 2023 Maha Chemicals (Asia) Pte Ltd