UV Light for Disinfection: Far-UVC Technology

A couple of researches has shown that the new far-UVC light with a wavelength of 222 nanometers is able to sanitize spaces and inactivate viruses effectively and safely.

Thermoplastic elastomers (TPE) is a type of polymeric material that combines the elastomeric behaviour of conventional elastomers and the processability of thermoplastics.

Some of its common usages include gasket sealings and soft-touch parts for applications such as handles and buttons. As 3D printing technologies evolve, 3D printers that adopt an open material feed system can now utilize TPE as part of printing jobs that require soft polymers.

Now you may be wondering, just how compatible are TPE materials for 3D printing? Here are some advantages of TPE for 3D printing:

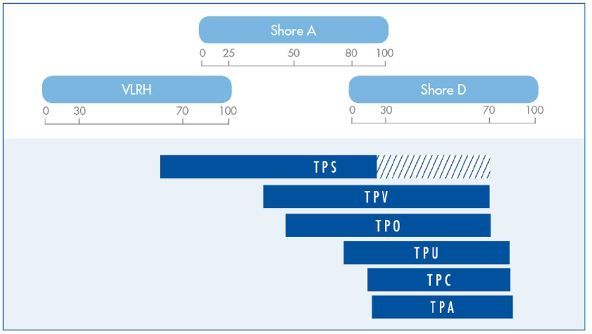

TPE materials are known to have a wide range of hardness. In particular, our partner, KRAIBURG TPE materials can range from super soft (<10 Shore A) to 66 Shore D.

While TPE materials may not be new to the market, achieving strict industry standards and approvals is essential in key markets. KRAIBURG TPE is a global TPE manufacturer in the automotive, consumer, industry and medical sector with numerous certifications.

Read on the find out which specific TPE material you should use for your industry!

A key feature about 3D printing is the ability to customize designs and parts to specific needs. Beyond technical specifications, color options may often be limited for other materials choices. Using TPE materials, you are no longer limited and have the freedom to select from a wide array of color options for your next print job!

TPEs can be customized to have different required properties to suit requirements such as haptic surface touch for handles or low surface friction for very smooth parts.

Regardless of your 3D printing job’s nature, unpleasant odorous materials are generally not welcomed. Emissions and odor may also disrupt your customer’s perception of your 3D print and hence deemed unacceptable. KRAIBURG TPE’s material emits close to no odor, allowing you to focus on the bigger picture.

As 3D printing continue to gain popularity, its usages may include greater outdoor activities and prototyping to conduct tests in the open. Hence, it is necessary for your material to withstand the harsh environment and climate – guaranteeing success for you or your customer’s testing on the grounds.

TPEs are free from these substances which are banned according to certain regulations or customer’s banned substances list

A key to maintaining business sustainability is to ensure environmental sustainability as well. There is a growing concern amongst consumers towards environmental issues as the world continues to experience greater climate changes.

More and more companies are looking towards making their business ethically sustainable to meet this concern. Understanding this need, we are proud to support KRAIBURG TPE in its efforts for sustainability with recyclable TPE materials for 3D printing.

Some ways that 3D printing has impacted the automotive industry include the extensive rapid prototyping, producing tooling anas well as end parts. An article by Autonomous Manufacturing shows some real life examples of 3D printing usage for several automative players.

As such, we suggest using THERMOLAST® K. This specific material is KRAIBURG TPE’s multi-purpose TPE compound that can be used in specialized fields for consumer and industry markets as well as the automotive market.

Evident from the COVID pandemic, the medical sector is essential and undergoes constant development with mandatory compliance to strict standards and international approvals.

As such, KRAIBURG TPE’s THERMOLAST® M TPEs have been specially developed for medical, pharmaceutical and diagnostic applications. This material has been tested to deliver high standards of safety with medical approvals like ISO10993-4, -5, -10, -11 and USP class VI.

Simply put, this range can be used for direct contact with body fluids and blood, which are common applications in the medical sector.

Prolonged usage of certain industrial power tools can result in damaging side effects to the body. To encourage workplace safety and increase the effectiveness in your industrial projects, try 3D printing protective seals and handles to reduce the irreversible damage using For Tec E®.

This material can be used to print 2-component seals in electronic applications and soft-touch handles. The material is resistant to skin oils, sun cream and olive oil. The compounds are characterized by their adhesion to polyamides such as PA 12, PA 6 and PA 6.6.

Wanting to incorporate 3D printing of TPE into your business but not sure where to start? Talk to us for a free consultation to determine whether 3D printing TPE can be adopted into your current manufacturing processes. Our team of professionals are always glad to provide you with sample design and cost analysis, to access your suitability.

Contact us at jiarong.teo@maha.asia / sales@maha.asia

A couple of researches has shown that the new far-UVC light with a wavelength of 222 nanometers is able to sanitize spaces and inactivate viruses effectively and safely.

I once inquired from a beer critic about the criteria for a top-notch glass of light beer, such as American lager or German pilsner. His response was, “I want to

Due to its significant impact on consumer preferences for food items, ensuring exact consistency in color is crucial. The color of food is closely linked to the biological, chemical, and

Copyright © 2023 Maha Chemicals (Asia) Pte Ltd