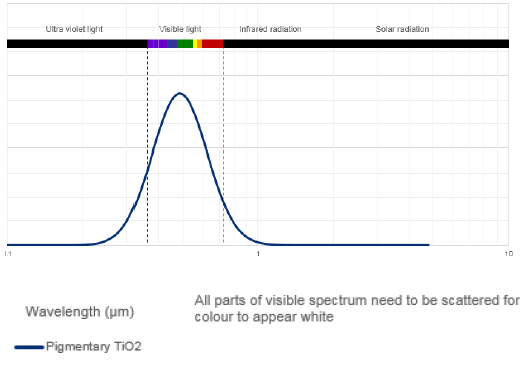

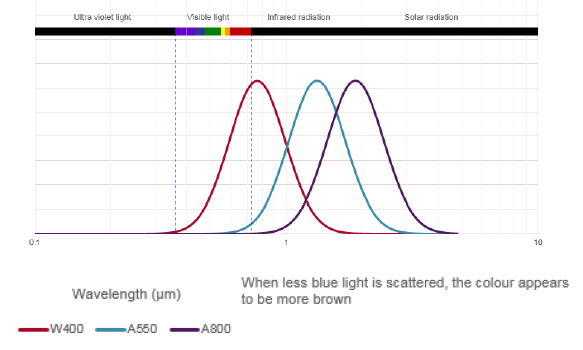

Selecting the right products for the reflective roof coating formulation is crucial to ensure consumers’ optimal LEED credit. In Maha Chemicals, we offer an award-winning range of TiO2 pigments from Venator called Altiris. These pigments are specially engineered to deliver enhanced solar reflective properties across broad color palettes. They can reflect both infrared and low-frequency visible lights (see figure 1). In addition to this application, Altiris pigments are also suitable for almost all exterior coatings applications, e,g., walls, coil, automative, marine coatings.

Reflective roof coatings are known for their viable role in the LEED rating process. Numerous studies have demonstrated their ability to reduce energy consumption, improve comfort, and extend the life of existing roofing systems and structures. To develop LEED-compliant reflective roof coatings, manufacturers need to select suitable products for their formulation

Introduction to Leed

LEED (Leadership in Energy and Environmental Design) is the most commonly used green building rating system worldwide. For the last two decades, various versions of LEED have pushed the global green building market forward progressively, with more than 93,000 registered and certified projects. Today’s version of LEED, LEED v4.1, offers six rating systems categories based on the project and building types. To understand more about LEED rating system, please visit: https://www.usgbc.org/leed

The Role of Reflective Roof Coatings in Leed Credits

Reflective roof coating is a specialty coating system with the ability to reflect lights and dissipate heat from roof surfaces. As a result, buildings are able to maintain their temperature low hence cut-off their energy usage during hot sunny weather.

According to a study conducted by the Reflective Roof Coating Institute (RRCI), reflective roof coatings have both direct and indirect contributions to LEED points. While these contributions are highly dependent on the coating’s material as well as the building type, the followings are a number of common LEED credits associated with the utilization of reflective roof coatings:

- Sustainable Sites: Heat Island Reduction (1-2 Credits)

- Energy and Atmosphere: Optimized Energy Performance (16-20 Credits)

- Material and Resources: Building Life-Cycle Impact Reduction (5-6 Credits)

- Indoor Environmental Quality: Thermal Comfort & Daylight (1-3 Credits)

More information about the evaluation criteria and credits earned can be found at this link

Our LEED-Compliant Solutions

Above figure is regular TiO2 pigments vs. Altiris® TiO2 pigments scattered light spectrum

To further enhance the quality, we recommend a high-performance Polyvinylidence Fluoride (PVDF) based resin from Arkema called Kynar Aquatec. A reflective roof coating formulated with Kynar Aquatec offers higher reflectivity and emissivity thereby further reducing roof surface tempreatures and limiting the heat transfered to the building’s interior. This helps reduce energy costs, improves occupant comfort, and reduces urban heat islands, which offer a significant contribution to LEED credits.

Kynar Aquatec based coating also promises an ultra-low maintance cost. This is attributed to their extreme weathereability, excellent dirt shedding, outstanding water repllency, and superb mildew resistance. Furthermore, they also offer high-performance solutions for metal restoration and repair projects, which also positively contribute to LEED credits.

For more information about Altiris and Kynar Aquatec application please contact our team at sales@maha.asia

RELATED POSTS

Discover cost-effective alternatives to TPGDA and TMPTA for UV coatings, offering savings of up to 18% while enhancing yellowing resistance and ensuring a safer working environment.

Discover Quava™ MHEC, a cost-effective waterborne coatings formulation.

Discover GEN TPA R2122, a water-based emulsion, corrosion-resistant alternative to solvent acrylic for direct-to-metal coatings. Contact us for more info!