Crowns that NEVER Fracture – Warranty for a Century

Your customer walks in and complains about a fractured crown. How can you produce crowns that never fracture? What if it comes with a 100-year warranty? Click here to find out more!

The appearance of a transparent or translucent product is described by total transmittance, haze and clarity. They are important parameters for plastic films, glass, food packaging, LCD panel, automotive windshields and other transparent and translucent products. Total transmittance is influenced by absorption and reflection, while Haze and clarity are interrelated which is influenced by the scattering of the diffused light.

If light scatters when it passes through a material, haze appear and compromise the clarity of the product. Transmission haze measurement is vital when the transparency is essential to ensure the clarity of a product. In order to maintain consistency of the transparency of a product, haze meter is used to measure the haze value to ensure it is within the establish reference standard. It helps to identify issue earlier for the necessary corrective actions, prevent additional cost involved due to rejected product and to ensure the quality of the product. Thus, haze can be controlled and minimized using a haze meter.

Transmittance / Total Transmittance

Total transmittance is the ratio of transmitted light to the incident light. Its equation is Transmittance= Tt/T1.

Tt: Transmitted light (as shown in pink color of picture 1)

T1: Incident light (as shown in the blue color of picture 1)

Haze: Wide Angle Scattering

Haze is how blurry or cloudy the appearance of a transparent material is. This measurement is defined by ASTM D1003. According to ASTM definition, haze is the percentage of light which passing through deviates from the incident beam greater than 2.5 degree on the average. Haze equation is Haze = Td/Tt.

Td: Scattered light which is greater than 2.5 degree (as shown in green color of picture 1)

Tt: Total transmitted light (as shown in pink color of picture 1)

Haze value is expressed in percentage, %. The lower the haze value, the higher the clarity. In general, 0% indicates complete transparency, while greater than 30% is considered to be diffusing or translucent. Below are some possible reasons that cause haze occurs in a product,

Clarity: Narrow Angle Scattering

Clarity refers to the transparency and purity of a transparent material, as well as how well very fine details can be seen through. It is determined by percentage of light which passing through deviates from the incident beam less than 2.5 degree. Clarity equation is Tn/(Tp+Tn).

Tn: Narrow angle scattered light (as shown in yellow color of picture 1)

Tp: Transmitted parallel light (as shown in the blue color of picture 1)

Looking for economic product for the haze and clarity measurement? Write in to Sales@maha.asia or contact us at 68631808.

Interested to read on? Click here for other relevant articles about haze measurement.

Your customer walks in and complains about a fractured crown. How can you produce crowns that never fracture? What if it comes with a 100-year warranty? Click here to find out more!

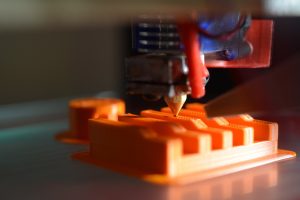

What is 3D printing work? How is it different from other manufacturing techniques? The answers to these questions might surprise you. There at several different types, there isn’t just one form of 3D printing. They all build parts by depositing material one layer at a time, but there are important differences in terms of 3D printing technologies, the materials supported, the part sizes that can be produced, and the accuracy, resolution and precision that the 3D printers can achieve.

How many hours in a weathering tester equals to a year of outdoor exposure? In this article, learn more about how you can make use of your weathering data more efficiently and factors you should look out when testing.

Copyright © 2023 Maha Chemicals (Asia) Pte Ltd