Maskne – The new acne! Is it a real thing?

Maskne is the word derived from “Mask” and “Acne”. It is a relatively new phenomenon observed during mandated mask wearing. Due to the coronavirus pandemic, we have seen exponential growth in the condition.

The demand for mild, skin-friendly surfactants is one of the drivers for the green surfactants market. These surfactants are likely to replace hasher conventional surfactants that may harm the skin. Furthermore, the increased awareness and regulation of 1,4 dioxane, a by-product found in many products has led to consumers seeking for sulfate-free options.

To cater to these demands, manufacturers are formulating products using green surfactants e.g. Alkyl Polyglucosides and amino acid surfactants and one major challenge they face is reaching their target viscosity. The most common way to thicken surfactant-based formulations is to use Sodium Chloride. However, this only works well for surfactant systems based on Sodium Laureth Sulfate (SLES) and Cocamidopropyl Betaine. Other gelling agents like Xanthan Gum, Cellulose types and Carbomer types are suitable for any formulation of high water content. Here, we have put together an overview on thickeners and a guide on green surfactants thickening that will help you select the right thickener to achieve your desired viscosity.

Thickening agents for surfactant systems are usually classified into 2 groups:

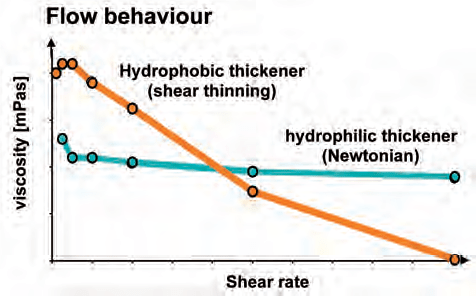

Hydrophobic thickeners provide a shear thinning flow behaviour where viscosity decreases with increasing shear rate. In contrary, hydrophilic thickeners has a Newtonian flow behaviour where viscosity is independent of the shear rate.

For hydrophobic thickeners, the viscosity is mostly stable at higher temperatures and it decreases at lower temperatures. However, for hydrophilic thickeners, the viscosity decreases dramatically at higher temperatures and increases significantly at lower temperatures.

Interested to try the thickeners mentioned in our green surfactants thickening guide? Contact us for free samples now!!

Maskne is the word derived from “Mask” and “Acne”. It is a relatively new phenomenon observed during mandated mask wearing. Due to the coronavirus pandemic, we have seen exponential growth in the condition.

Not able to find a suitable Thickeners for Glutamate and other Amino Acid Surfactants? We have an excellent solution for you. Find out more about our thickener, Thickmate A, from here!

Here are the top skincare trends for 2023, handpicked by experts and guaranteed to stay! Explore skin minimalism, body care and more in this article. Read on to find out more.

Copyright © 2023 Maha Chemicals (Asia) Pte Ltd