Additive Manufacturing VS Subtractive Manufacturing

Heard of 3D printers and additive manufacturing…but what exactly is it? And what about subtractive manufacturing? What exactly are their differences?

As a manufacturer of polyester powder coatings for architectural applications with principal customers in the building and construction industry, they were most concerned about outdoor elements such as climates and weather conditions and its impact on building structures and surfaces.

Besides the importance of keeping up with reputation, such weathering testing help to ensure the durability of materials as a key component in their product development strategy. Their analysis shows that primary polymer degradation type includes colour change and gloss loss.

The manufacturing has just purchased new fluorescent UV testers but were experiencing consistency and stability problems in conducting its weathering test.

This particular test was according to ASTM G154 (for >500 hours), with a Gloss Loss value of >50%, representing their critical failure mode. This test was chosen as it is an internationally recognized standard for architectural and steel coatings.

The new UV testers could not deliver Gloss Loss or Colour results that were stable, consistent, or comparable. The manufacturer’s repair representative spent a considerable amount of his own time over a three-year period attempting to get the testers to provide usable, stable, and consistent results, without success.

The inconsistent performance of the competitive apparatuses led the manufacturer to seek out another distributor, Q-Lab, who was well-known in the industry to work on a solution for the accelerated weathering testing needs.

Q-Lab agreed to run a 500-hour test using three QUV/se testers to verify that test results met DSM’s expectations. They provided two colours of samples for each QUV apparatus – a brown and a white.

The expectation is that the darker colour will lose gloss faster than the lighter colour, with the manufacturer providing an expectation for the amount of expected Gloss Loss and the timescale involved.

The result was that all three instruments provided results that not only fulfilled the criteria for providing comparable results between the three testers, but also fell within the time parameters laid down by the manufacturer.

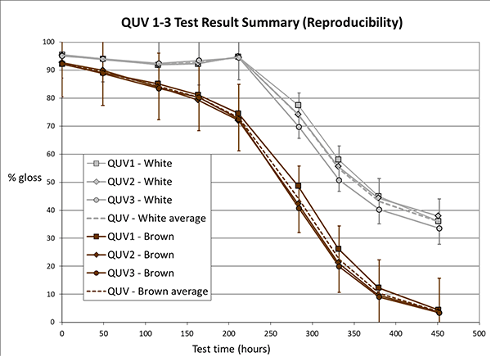

The three graphs below show the repeatability of testing by the three apparatus. In each graph, the y-scale represents % gloss retention. The upper grouping of gray lines represents gloss measurements taken from white specimens; the lower grouping is from brown specimens.

The final graph averages all white and all brown specimen measurements from each of the three QUV accelerated weathering testers (solid lines) as well as the overall average from all three testers (dashed lines) shown with error bars. This demonstrates the reproducibility of results observed among the three test instruments.

Consistent gloss and colour test results from their new QUV testers, provided the manufacturer with added confidence in their new accelerated and outdoor test programme for new coatings developments. They were able to quickly screen out new developments in the laboratory before spending resources to put them to the true test of outdoor weathering.

Maintain quality materials with a robust and trustworthy test programme from internationally recognized weathering testers such as Q-Lab QUV. Make better decisions efficiently, reducing risk of damage to your reputation and relationships.

Contact us today for your accelerated weathering testers at sales@maha.asia

Heard of 3D printers and additive manufacturing…but what exactly is it? And what about subtractive manufacturing? What exactly are their differences?

Share on facebook Share on linkedin Share on whatsapp Share on telegram Share on email Pada beberapa industri dan aplikasi biofarma, pengukuran warna merupakan hal yang sangat penting untuk memastikan

Looking to implement a colour quality control program for your business? Here are 5 important components to ensure and maintain a successful QC programme.

Copyright © 2023 Maha Chemicals (Asia) Pte Ltd