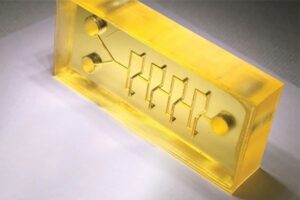

Revolutionizing Microfluidics: The Power of 3D Printing Technology

Revolutionizing Microfluidics: The Power of 3D Printing Technology The Power of 3D Printing Technology Microfluidics, the science and technology of manipulating fluids at the microscale, is rapidly gaining importance in