Your Guide to 3D Printers 2019

Want to purchase a 3D printer but not sure which one to select? Want to know more about the various technologies, and what is latest in the market?

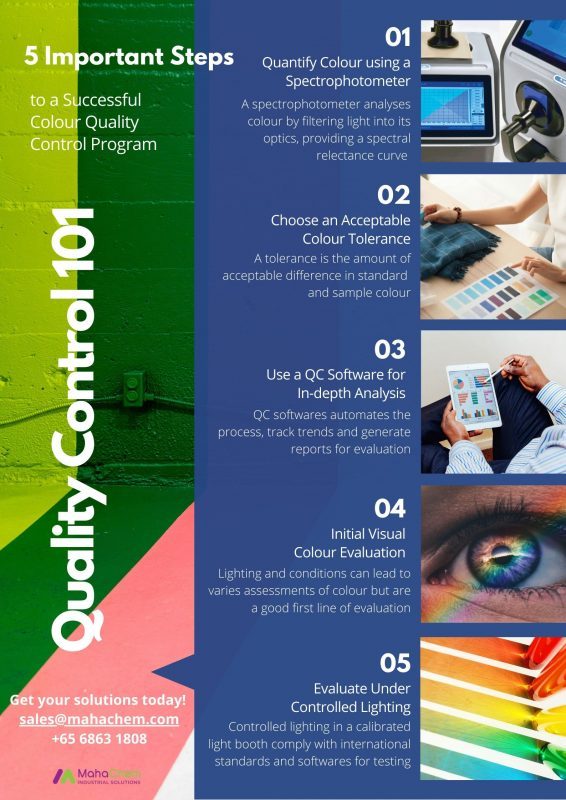

Quality Control (QC) is important in ensuring that product produced remain of consistent quality. Colour QC verifies that the colour manufactured remains the same throughout different product batches.

Having a QC programme in place not only helps to maintain your quality of products but also helps you to accurately communicate colours with your partners. Efficiently reduce cost and wastage by inspecting raw materials before actual production and before sending them to customers.

Relying solely on the human vision will not achieve the exact specific colour and can lead to immense resource wastage just to replicate the same colour without a specific universal data that can pinpoint the colour desired.

Using a spectrophotometer allows for accuracy and comparison of spectral data that can be quantified and easily communicated to different parties.

A spectrophotometer is able to precisely measure the electromagnetic energy at a specific wavelength of light to identify the colours and determine how much of that colour is present. The analysis will show a spectral reflectance curve, also known as the colour’s “fingerprint” as it is unique to that colour.

Tolerance is the amount of acceptable difference between the colour standard set and the colour sample produced.

Setting the right tolerance range is important:

There are many different types of colour models that most are familiar with, including RCB, CMYK and PMS. In a laboratory, the most commonly used colour space is CIELab or CIE L*a*b as they are the most complex but robust for quantitative comparisons.

A quality control software always you to automate most processes and is able to provide you with tracking capabilities, trends and generate reports to gather insights from.

QC software can compare production colours against pre-set standards, use tolerances to determine a pass or fail status and notify you before it goes out of the tolerance.

Be it working on a global supply chain or managing your own products, a QC software definitely makes it easier to track your colour data in an efficient manner.

As an initial evaluation, comparing colour visually is the most effective method. While it is not sufficient, it provides opportunities for discussion and insights on the tolerance levels for your colours.

As humans, everyone usually see colour differently, hence those who are involved in a visual evaluation are encouraged to take and pass the Farnsworth-Munsell 100 HueColor Vision Test to determine there are any vision deficiency that may affect the colour test.

Natural lighting is subjective and different for most people, depending on the climate, timing and more. Lighting in a public place may also be influenced by many other variable factors such as wear and tear, space and shadows.

Hence, the best way to test your product’s colour is in a controlled light booth. The calibrated lighting booth is equipped with light sources that adhere to CIE International Standards and can also be easily incorporated with your QC software.

Set up your Colour Quality Program with us today! From choosing the right spectrophotometer to tolerance levels or even implementing QC software, our professionals are here to support you.

Contact us at sales@maha.asia to find out more!

Want to purchase a 3D printer but not sure which one to select? Want to know more about the various technologies, and what is latest in the market?

Share on facebook Share on linkedin Share on whatsapp Share on telegram Share on email China adopting Lumenizer 300 Lumenizer used by Team China during Tokyo Olympics 2020 Throughout the

Open material 3D printers can now utilize soft polymers such as TPE, a polymeric material with elastomeric behavior and processability of thermoplastics. Find out more about it’s benefits!

Copyright © 2023 Maha Chemicals (Asia) Pte Ltd