A cost-effective substitution for TPGDA and TMPTA

Discover cost-effective alternatives to TPGDA and TMPTA for UV coatings, offering savings of up to 18% while enhancing yellowing resistance and ensuring a safer working environment.

AQUACRYL™ PUD 6000 is a unique aliphatic polycarbonate polyurethane dispersion with outstanding hardness, excellent water, and alkali resistance, and good chemical resistance for use in various Industries. It is mainly used in concrete coatings, floor and wall coatings, multi-surface coatings, and wood coatings.

It has been successfully tested and used in high-performance one-component waterproofing membranes. Below are the lab test results:

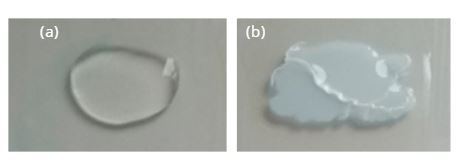

The water spotting test showed that the dry film of AQUACRYL™ PUD 6000 did not turn whitish after 24 hours which indicate very good water resistance.

AQUACRYL™ PUD 6000 is formulated with an Acrylic/PUD hybrid emulsion, AQUACRYL™ 2519 at an 83:17 ratio in a waterproofing membrane formula to achieve a balance of cost and performance (Sample A). We also included a market-proven waterproofing paint as a control in this test (Sample B). Three tests were conducted as follows:

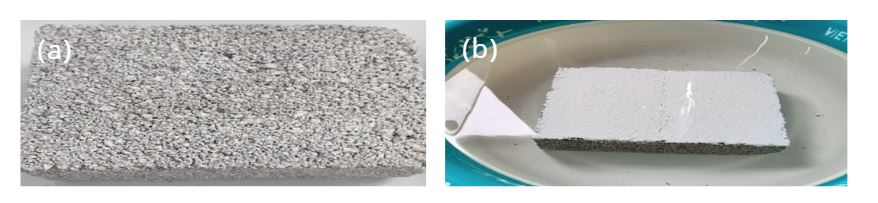

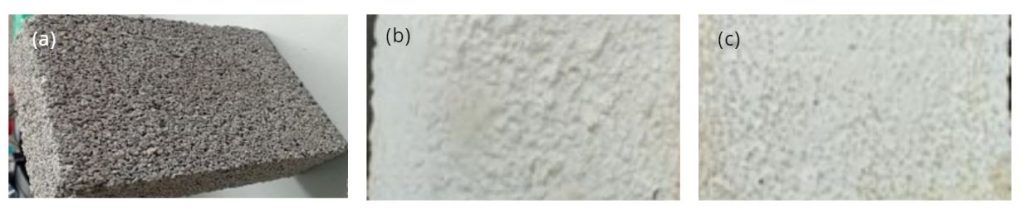

Two coats of waterproofing membrane were applied on the surface of the concrete panel with one-hour of drying in between coats. The coating was air dried for 24 hours and was further dried in a 50°C oven for 12 hours. The back of the coated panels was then immersed in the water as shown below. After 30 days of testing both samples, A and B are stable and did not show any blistering on the surfaces.

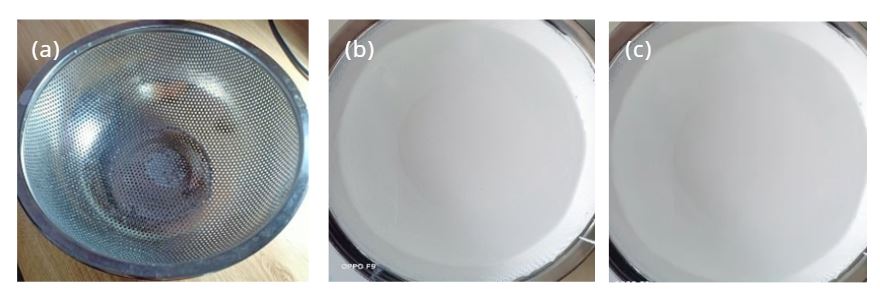

Three coats of waterproofing membrane were applied to the mesh cup with one hour of drying in between coats. The coating was air dried for 24 hours and was further dried in a 50-degree C oven for 12 hours. Water was then placed inside the coated mesh cup.

After 30 days of testing both samples, A and B have no blistering and no leaking of water.

Two coats of waterproofing membrane were applied on the surface of concrete panel with one hour drying in between coats. The coating was air dried for 24 hours and was further dried in a 50°C oven for 12 hours. The back of the coated panels was then immersed in a solution containing 5% sodium hydroxide and 5% sodium chloride.

After 5 days of testing, there is no change in appearance for both samples.

After 20 days, film of sample A started to wrinkle and film of sample B appeared yellowish and delamination.

The above test results showed that the waterproofing membrane consisting of AQUACRYL™ PUD 6000 and AQUACRYL™2519 has the same performance as the market standard in water resistance and has outperformed the market standard in salt and alkaline resistance. To understand more about this product, please contact our team of professionals at sales@maha.asia.

We Offer A Wide Range Of Ingredients For Surface Technology Formulations!

Discover cost-effective alternatives to TPGDA and TMPTA for UV coatings, offering savings of up to 18% while enhancing yellowing resistance and ensuring a safer working environment.

Discover Quava™ MHEC, a cost-effective waterborne coatings formulation.

Discover GEN TPA R2122, a water-based emulsion, corrosion-resistant alternative to solvent acrylic for direct-to-metal coatings. Contact us for more info!

DEGAROUTE®: Innovative cold plastic road markings for durability and safety. Contact Maha Asia for details.

TRIS AMINO Crystals is well-known provides high-efficiency formaldehyde scavenging functionality when used in indoor air filtration applications as well as in decorative paints and building and construction material

Orgasol® Fine Powder Essential for Overprint Varnishes (OPV), enhancing print durability, performance, and aesthetics

Copyright © 2023 Maha Chemicals (Asia) Pte Ltd