A cost-effective substitution for TPGDA and TMPTA

Discover cost-effective alternatives to TPGDA and TMPTA for UV coatings, offering savings of up to 18% while enhancing yellowing resistance and ensuring a safer working environment.

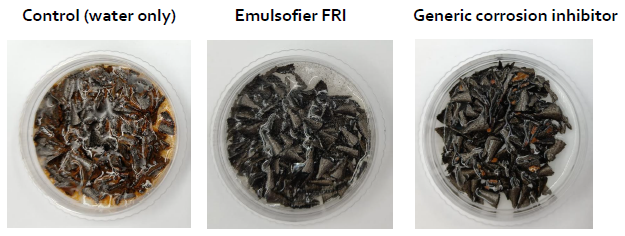

Flash corrosion is a severe problem for all water-borne-type coatings on steel. This type of corrosion occurs from the steel bleeding through the coat, leading to staining within hours after the coat has been applied. Flash corrosion occurs quickly, especially when thin water films reside on the steel surface, triggering the corrosive action. Most of the time, the corrosion products are soluble and capable of migrating within the coat and resulting in a stain

Emulsofier FRI is a flash rust inhibitor typically used in metal surface protection, waterborne metal coatings, and other water-based formulations. The benefits of using this are:

Excellent flash rust inhibition and corrosion protection with low dosage

Organic based with low toxicity and high renewable content

Water soluble easy to incorporate into formulation

It can be applied on Acrylate emulsion based direct to metal coatings, PUD direct to metal coatings and water based alkyd coatings. Emulsofier FRI also provides superior corrosion protection to cast iron

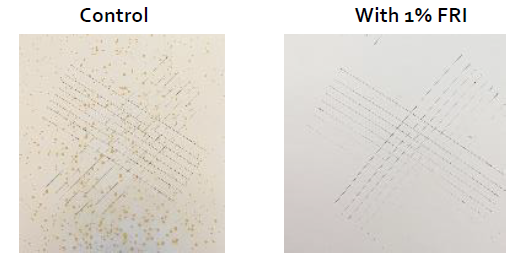

Below image is Flash Rust Inhibition & Adhesion 28% PVC paint At 1% dosage of Emulsofier FRI in 28% PVC paint, coatings on cold rolled steel shows excellent flash rust inhibition

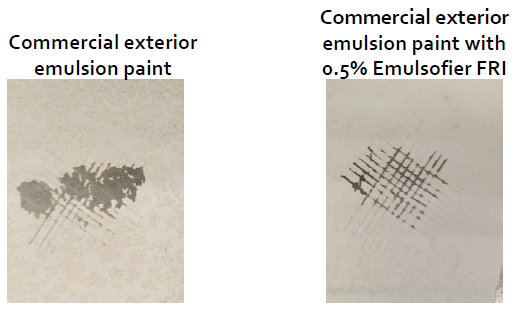

Flash Rust Inhibition post add to commercial decopaint.

When post added to a commercial premium exterior emulsion paint, Emulsofier FRI shows good flash rust inhibition and adhesion improvement on cold rolled steel.

Recommended Dosage

Amount of product (as supplied) with below recommended levels based on total formulation weight:

For more information about Emulsofier FRI application please contact our team at sales@maha.asia

We Offer A Wide Range Of Ingredients For Surface Technology Formulations!

Discover cost-effective alternatives to TPGDA and TMPTA for UV coatings, offering savings of up to 18% while enhancing yellowing resistance and ensuring a safer working environment.

Discover Quava™ MHEC, a cost-effective waterborne coatings formulation.

Discover GEN TPA R2122, a water-based emulsion, corrosion-resistant alternative to solvent acrylic for direct-to-metal coatings. Contact us for more info!

DEGAROUTE®: Innovative cold plastic road markings for durability and safety. Contact Maha Asia for details.

TRIS AMINO Crystals is well-known provides high-efficiency formaldehyde scavenging functionality when used in indoor air filtration applications as well as in decorative paints and building and construction material

Orgasol® Fine Powder Essential for Overprint Varnishes (OPV), enhancing print durability, performance, and aesthetics

Copyright © 2023 Maha Chemicals (Asia) Pte Ltd